The ring test is an effective method of detecting a defect in grinding wheels that are

over 4 inches in diameter. The wheels can’t be mounted during as that inhibits the

ring. The grinding wheels should be free from dust or grease buildup, and they should

be dry as water within the wheel’s porous structure also deadens the sound.

How to do the test:

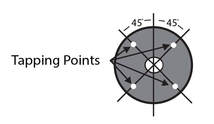

- Suspend the wheel with a tool handle or your finger through the arbor hole in the

wheel. - Tap the flat side of the wheel with a light nonmetallic

implement, such as a screw driver handle, at an

area 45 degrees from the vertical center line on each side

of the wheel and 1 – 2 inches from the edge of the wheel.

(see illustration) - Rotate the wheel 45 degrees and repeat the test until the

entire wheel has been tested.

all four points. If the wheel sounds dead (dull thud) at any of the four points, it is

cracked or damaged internally. Do not use it.

RSS Feed

RSS Feed